Food safety standards in the United States have undergone significant changes in recent decades due to legislation such as the Food Allergen Labeling and Consumer Protection Act (FALCPA) and the FASTER Act. For food safety professionals, the Food Safety Modernization Act is a critical but often overlooked piece of legislation that has significant consequences due to the enhanced powers it gives the FDA.

What is the Food Safety Modernization Act?

First signed into law on January 4, 2011, the Food Safety Modernization Act (FSMA) introduced significant amendments to the Food, Drug, and Cosmetic Act (FD&C Act). The act primarily focuses on introducing preventive measures to reduce the risk and spread of foodborne illnesses rather than relying on reactive measures. When health risks from food cannot be prevented, the FSMA also provides steps to ensure the products in question are quickly identified and removed from the market, such as enhanced traceability for ingredients and expanded authority given to the FDA.

FSMA did not just amend the FD&C Act; it also established a more proactive approach by introducing seven significant rules to improve food safety, including standards for produce safety, preventive controls for human food, and a Foreign Supplier Verification Program (FSVP).

Two of the act’s most significant aspects are the updates to Current Good Manufacturing Practices (CGMPs) and the introduction of Hazard Analysis Risk-Based Preventive Controls (HARPC). Both CGMPs and HARPC are established in Title 21, Part 117 of the Code of Federal Regulations.

Current Good Manufacturing Practices (CGMP)

CGMP is a series of regulatory food safety guidelines that food manufacturers must adhere to

These guidelines are presented to ensure a high level of hygiene and food quality throughout the food production process, while highlighting process controls to prevent any quality deviations. Ultimately, the purpose of CGMP is to ensure that businesses in the United States produce safe food.

As part of the updates to CGMP under the Food Safety Modernization Act, employees of food businesses are required to undergo education and training to understand food hygiene and safety practices better and ensure that food that is being manufactured, processed, packaged, or held in the business’s facilities is clean and safe. Explicit regulatory text defining and stating the importance of addressing allergen cross-contact in the workplace is also introduced. CGMP also ensures the design of food production facilities allows for adequate sanitary and maintenance operations, such as proper storage of foods to reduce allergen cross-contact.

Hazard Analysis Risk-Based Preventive Control (HARPC)

The HARPC focuses on food safety, emphasizing preventative measures to reduce the risk of food safety hazards, particularly those related to allergen risks. For businesses, this should help reduce the risk of recalls, which can be time-consuming and costly.

While similar to a HACCP plan and developed using HACCP principles, HARPC is considered a more comprehensive food safety plan. While a HACCP plan implements “Controls” (actions that can prevent, eliminate, or reduce potential hazards) at critical control points, HARPC also implements controls at other steps in the food safety plan. HARPC contains five main preventive controls (Process Controls, Food Allergen Controls, Sanitation Controls, Supply Chain Controls, and Other Controls), while the majority of controls under a HACCP plan fall under Process Controls. To learn about potential hazards, visit our food recall page, which provides detailed information.

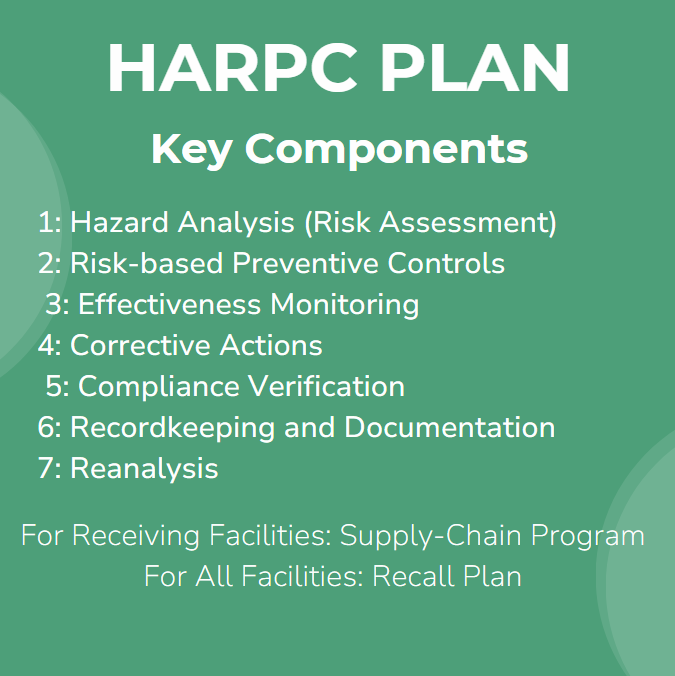

The USDA states that the following are considered key components of an HARPC plan:

Under FSMA compliance, all businesses that manufacture, process, pack, or store food must have a documented HARPC plan, which FDA guidance states must be re-analyzed at least every 3 years. There are some exceptions, however; foods under USDA jurisdiction, such as certain meat, poultry, and egg products, still require a HACCP plan. Similarly, juice and seafood products under FDA jurisdiction also require a HACCP plan due to regulations that were put in place before the FSMA Act.

The following records must be stored and documented:

- The hazard analysis

- Preventive controls for each identified hazard and verification that they effectively control the hazards

- Monitoring records to verify that preventative controls are correctly performed

- Documentation of any corrective actions taken

- The supplier approval and verification program

- The recall plan

- All testing and auditing results

- The results of the food safety plan reanalysis

Food Recalls under the FSMA

One of the most significant consequences of incorrect food allergen labeling for businesses is the risk of food recalls. Food industry recalls can easily cost millions of dollars and be incredibly time-consuming. When a food recall occurs, the operation must inform relevant parties, such as food manufacturers along the supply chain, set up public relations (PR) activities, and communicate this information to consumers, potentially diverting time away from other critical tasks.

With the passing of the Food Safety Modernization Act, the FDA has been given increased authority to enforce food recalls. For food products considered “adulterated or misbranded” or a risk to consumer health, a voluntary recall notice will be issued using the guidance provided under 21 CFR 7 of the Code of Federal Regulations.

If the business doesn’t comply, the FDA can issue a mandatory recall under Section 423 of the Food, Drugs, and Cosmetics Act, added by Section 206 of the Food Safety Modernization Act. While voluntary recalls are most common, mandatory recalls are issued when the FDA determines that the product poses a serious health risk.

With these new authorities, the FDA can issue recalls more quickly than before. Businesses are also better equipped to handle this prospect due to the preventative measures the FSMA introduced, such as enhanced traceability measures and mandatory recall plans. We have a dedicated page on the subject to learn more about food recalls and their impact on businesses in the U.S.

However, food recalls can still be devastating from both a financial and reputational perspective. For businesses looking to enhance their food safety processes, LiberEat’s food safety software offers a proactive approach to allergen management by identifying errors in allergen data and correcting them before they reach a consumer, saving you from potential damages.

There has never been a more critical or relevant time for integrating such software with existing FSMA-compliant processes, such as HARPC and CGMPs, to achieve a more seamless solution.

Software like LiberEat can effectively complement the FSMA’s traceability rules and allergen management requirements, ensuring manufacturers comply with its stringent standards.

LiberEat Allergen Detection Software

LiberEat’s food safety technology helps prevent errors in allergen data on supplier specifications, website and app data, food packaging, and menus. Early error detection can help protect your customers from major allergens. Properly managing and reviewing your allergen data is essential for keeping you and your customers safe.

Errors in allergen data can lead to potentially devastating allergic reactions and costly product recalls. For your peace of mind, contact us to learn more about how LiberEat can help protect your business.

Sources

Current Good Manufacturing Practice (CGMP) Regulations | FDA

Draft Guidance for Industry: Hazard Analysis and Risk-Based Preventive Controls for Human Food | FDA

Overview: HARPC and HACCP | USDA

How Much Does a Food Recall Really Cost? | Quality Assurance Magazine

FSMA Final Rule for Preventive Controls for Human Food | FDA